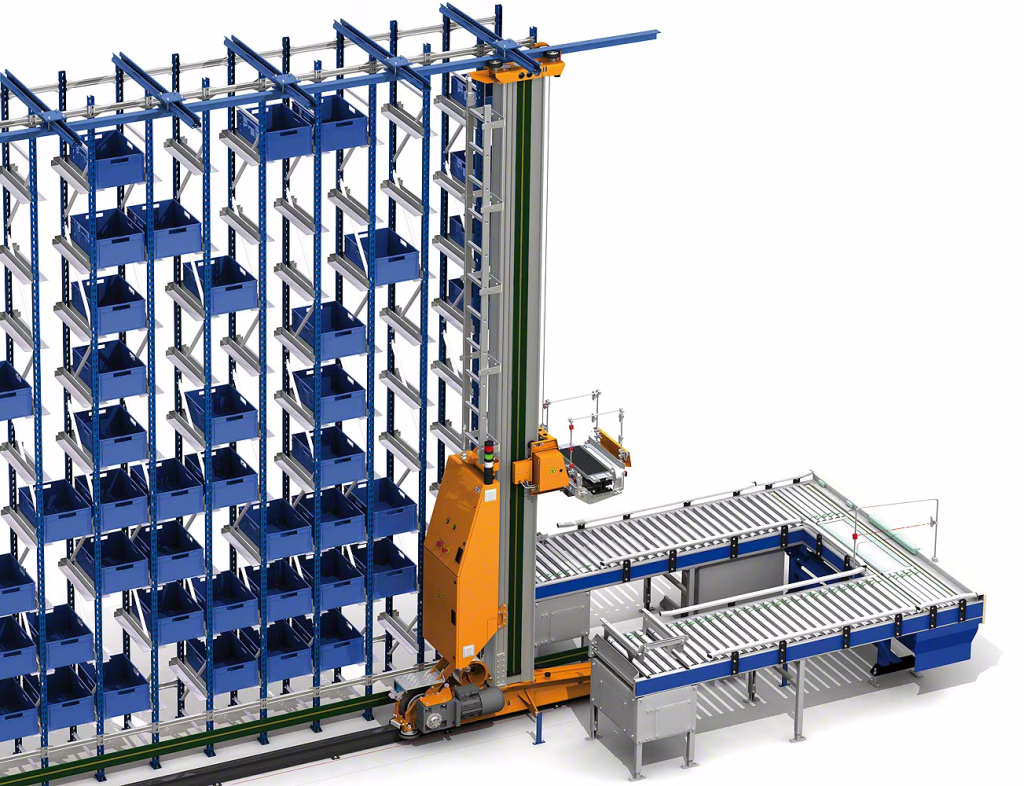

The automated warehouse storage system for boxes or trays is an integrated solution combining shelving, machinery, and warehouse management software. This system features a central aisle where a stacker crane operates, flanked by two racks that store the boxes or trays. The picking and handling area, equipped with conveyors, is situated either at one end or along the side of the racking system. In this area, the stacker crane delivers the load extracted from the rack. The conveyors transport the box to the operator, who performs the necessary tasks before the box is returned to the stacker crane. The stacker crane then places the box back in the racking. A comprehensive management software controls the entire system, tracking the location of all materials and maintaining a real-time inventory of the warehouse.

STACKER CRANES FOR BOXES ADVANTAGES

- Product-to-Operator Principle: This system efficiently brings the products directly to the operator, streamlining the workflow and increasing productivity.

- Automated Entry and Exit Operations: The automation of product entry and exit processes ensures smooth and reliable handling, reducing the need for manual intervention.

- Real-Time Inventory: The system maintains a continuous and accurate inventory, providing real-time updates on the status and location of all items.

- Error Elimination: By automating warehouse management, the system significantly reduces errors associated with manual handling and management.

- Space Optimization: The design makes optimal use of the available space, maximizing storage capacity and improving overall warehouse efficiency.

- Enhanced Comfort and Accessibility: The system provides maximum comfort and easy access to stored boxes, making retrieval and storage operations more convenient for operators.

In addition to being very practical, with these racks, we’ve eliminated aisles and streamlined storage tasks

Marina Xicola

Operations Manager

SHAD

(Barcelona, Spain)

RELATED PRODUCTS

Pallet Racking

Pallet Racking