Drive-In Pallet Racking Systems

Drive-in racking is a high-density storage solution designed to maximize warehouse space by eliminating aisles. This system allows forklifts to drive directly into storage lanes for easy loading and unloading, making it perfect for storing large quantities of similar items. Drive-in and drive-through racking systems provide excellent space utilization, ideal for industries with a high turnover of goods. Built with durable materials, these racks ensure long-lasting performance and efficiency. Suhong Storage Rack offers customized drive-in pallet racking systems tailored to meet Saudi Arabia’s unique storage needs, ensuring reliability and optimized operations for warehouses.

Benefits of Drive-In and Drive-Through Racking Systems

- Maximized Storage Space: Drive-in and drive-through racking systems provide exceptional space optimization, accommodating up to 75% more pallets by eliminating aisles. Ideal for high-density storage in Saudi Arabia, Dammam, UAE, Dubai, Qatar, and beyond.

- Efficient Inventory Management: These racking systems are perfect for FIFO (First-In-First-Out) or LIFO (Last-In-First-Out) inventory rotation. This flexibility is vital for industries with time-sensitive products, like in Riyadh or Tel Aviv warehouses.

- Cost-Effective Solution: With fewer aisles and increased storage capacity, these systems reduce the cost per pallet position, making them an economical choice for businesses in Kuwait, Jerusalem, and other regions.

- Enhanced Safety: Designed to ensure stability, these racks withstand heavy loads and provide secure storage, meeting industrial safety standards across Middle Eastern markets.

- Customizable Design: Tailored to specific storage needs, the drive-in pallet racking system adapts to varying pallet sizes and weights, making it versatile for diverse applications in Qatar and Dubai.

- Quick Installation: With modular components, these systems are easy to install and relocate, ensuring minimal disruption to operations in fast-paced warehouse environments.

Since we installed the Drive-In Racking system, our warehouse space has been maximized, and managing our inventory has never been easier!<

Operations Manager

SF EXPRESS

(China, Shanghai)

DRIVE-IN RACKING APPLICATIONS

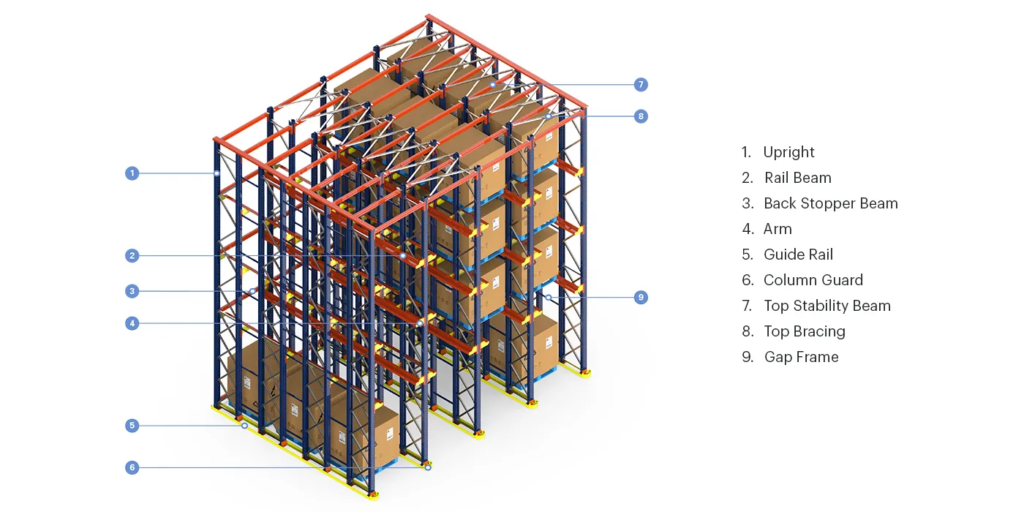

DRIVE-IN RACKING COMPONENTS

FAQS

About the Characteristics of Drive-In Racking

Drive-in pallet racking is a high-density storage system designed to maximize space utilization by allowing forklifts to drive directly into the racking lanes. It is ideal for storing large quantities of similar products.

Drive-in racking eliminates the need for aisles between racks, enabling compact storage. This system is perfect for warehouses in Saudi Arabia, Dammam, Dubai, and other regions with high real estate costs.

Drive-in racking systems are typically constructed from durable steel to handle heavy loads. This makes them a reliable choice for warehouses in the UAE, Riyadh, and Tel Aviv.

The system includes side rails and guides to ensure stability and safety during forklift operations. It is commonly used in high-demand areas like Dubai, Dammam, and Kuwait.

Yes, drive-in racking systems are versatile and can be adjusted to fit different pallet sizes, making them suitable for businesses in Riyadh and Qatar.

Drive-in racking supports Last-In, First-Out (LIFO) inventory management, which is ideal for products with longer shelf lives, common in industries in Jerusalem and Tel Aviv.

No, while similar, drive-through racking allows forklifts to enter and exit from both ends of the rack, supporting First-In, First-Out (FIFO) inventory management.

Drive-in racking systems are designed to handle heavy loads, making them ideal for industries in Saudi Arabia and the UAE dealing with bulk storage.

Safety features include sturdy beams, guides, and rail systems to minimize risks during forklift operations, especially in high-traffic areas like Qatar and Dubai.

Yes, drive-in racking systems can be tailored to meet specific storage needs, offering flexibility for warehouses in Jerusalem and Riyadh.

The Uses of Drive-In Racking

Drive-in racking is ideal for industries requiring high-density storage, such as food and beverage, manufacturing, and retail in Saudi Arabia and the UAE.

Drive-in racking is ideal for industries requiring high-density storage, such as food and beverage, manufacturing, and retail in Saudi Arabia and the UAE.

Drive-in racking is commonly used in cold storage facilities to maximize space and efficiently store frozen products in locations like Riyadh and Dammam.

Yes, it is perfect for storing seasonal inventory, allowing businesses in Kuwait and Dubai to optimize space during peak demand periods.

Manufacturers in Tel Aviv and Jerusalem use drive-in racking to store raw materials and finished products in bulk, improving warehouse efficiency.

Yes, automotive companies in Riyadh and Dammam use drive-in racking to store heavy and bulky components securely.

Beverage companies in Qatar and the UAE use drive-in racking for its ability to store high volumes of uniform products like bottled drinks.

Drive-through racking facilitates FIFO inventory management, which is crucial for perishable goods storage in Dubai and Kuwait.

While designed for bulk storage, drive-in racking can handle moderate turnover rates, making it suitable for warehouses in Saudi Arabia and Tel Aviv.

Drive-in racking helps organize inventory efficiently by creating dedicated lanes for specific products, a practice widely adopted in Dammam and Riyadh.

Yes, by optimizing storage space and reducing energy use in warehouses, drive-in racking contributes to sustainability efforts in Jerusalem and Qatar.

RELATED PRODUCTS

WIRE MESH DECKING

VNA RACK :VERY NARROW AISLE RACKING

RACK UPRIGHT PROTECTOR

DRIVE-IN RACKING

PUSH-BACK RACKING

PALLET FLOW RACKING

SHUTTLE RACKING