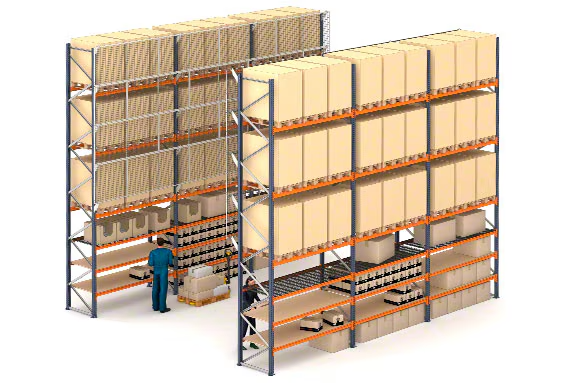

Selective Pallet Racking System

Our Selective Pallet Racking System is designed to provide efficient and accessible storage for a wide range of goods. Ideal for warehouses and distribution centers, this system allows easy access to each pallet, ensuring fast retrieval and optimal use of space. With adjustable levels, it offers flexibility in height and width to accommodate various pallet sizes. The robust steel construction guarantees durability and safety, making it a reliable solution for businesses in Saudi Arabia. Whether for selective storage or maximizing warehouse capacity, this racking system is perfect for enhancing operational efficiency.

Selective Pallet Racking System Benefits

- Maximized Storage Efficiency: The selective pallet racking system allows for optimal use of space while providing easy access to each pallet, making it ideal for warehouses and storage areas in Dammam, Dubai, and beyond.

- High Visibility: The design of selective racking ensures that each pallet is clearly visible, which improves inventory management and reduces the time spent searching for goods.

- Adaptability: Selective racking is easily customizable to suit varying pallet sizes and storage needs, making it suitable for diverse industries.

- Easy Access: Each pallet is directly accessible, reducing handling time and improving the speed of operations in busy warehouses.

- Cost-Effective: As one of the most affordable racking systems, selective storage racking offers great value without compromising on performance.

- Durable & Long-Lasting: Built with high-quality materials, selective racking systems are robust and designed to last, providing long-term benefits for businesses in Riyadh and other regions.

Pallet racks are the ideal solution for managing our orders and maximizing our storage capacity.

APPLICATIONS OF PALLET RACKING

An ideal solution for a wide variety of SKUs.

Storage of Multiple SKUs

3PL Warehouses

Facilities of All Sizes

Non-Palletized Goods

Double-Deep Racking

Order Picking

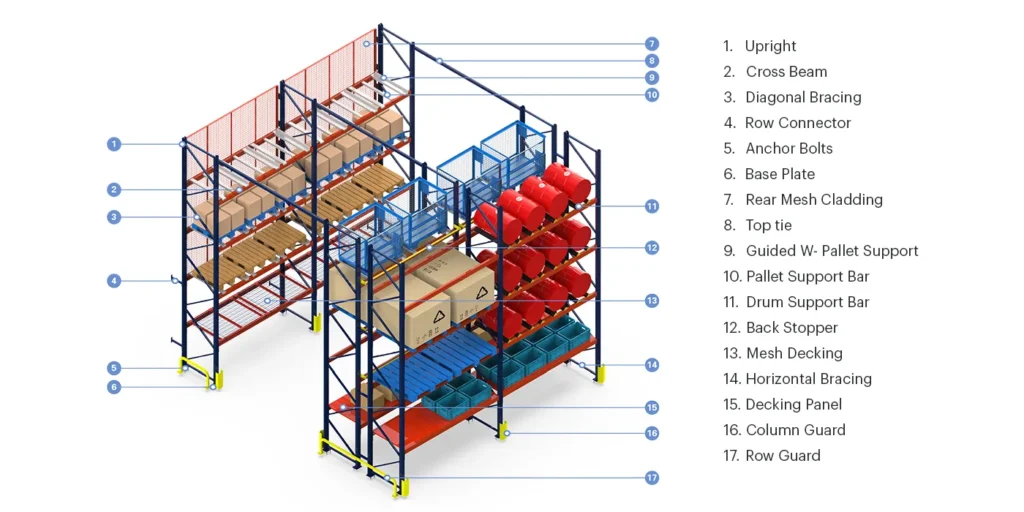

SELECTIVE PALLET RACKING COMPONENTS

Extremely flexible solution adaptable to different types of warehouses

FRAMES

BEAMS

SAFETY LOCKING MECHANISM

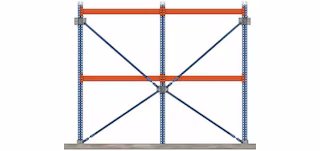

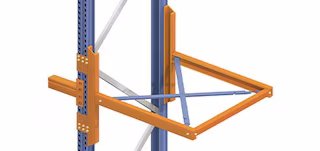

SPINE BRACING

FRAME FOOTPLATES

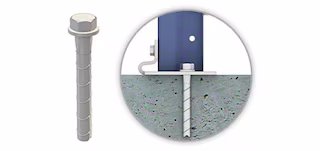

ANCHOR BOLTS

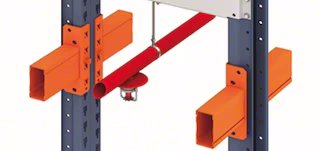

ROW SPACER

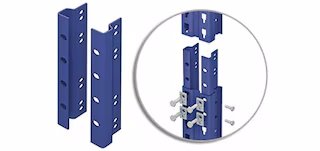

FRAME SPLICE

PALLET RACK PROTECTORS

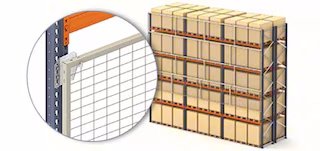

FALL-PROTECTION MESH

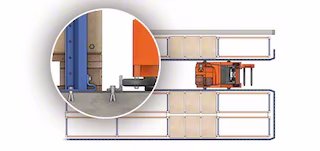

GROUND-LEVEL PASSAGEWAYS

SAFETY PROFILE

GUIDANCE SYSTEMS

FIRE SAFETY SYSTEMS

PALLET RACKING ACCESSORIES

Extremely flexible solution adaptable to different types of warehouses

METAL SHELVES

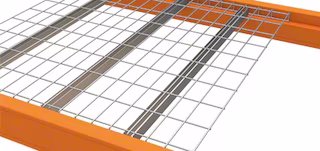

MESH SHELVES

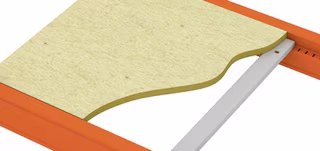

CHIPBOARD SHELVING

CONTAINER SUPPORT BARS

DRUM AND REEL SUPPORTS

RAISED PALLET SUPPORT BARS

PALLET SUPPORT BARS

P&D STATIONS

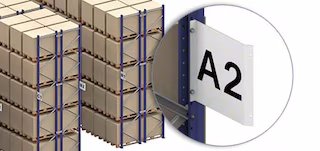

AISLE SIGNS

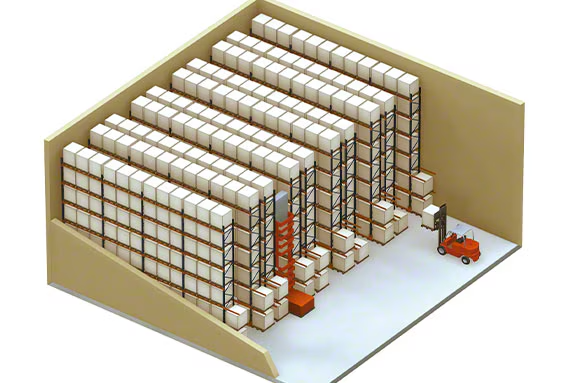

CONFIGURATIONS

Storage solution available in multiple combinations

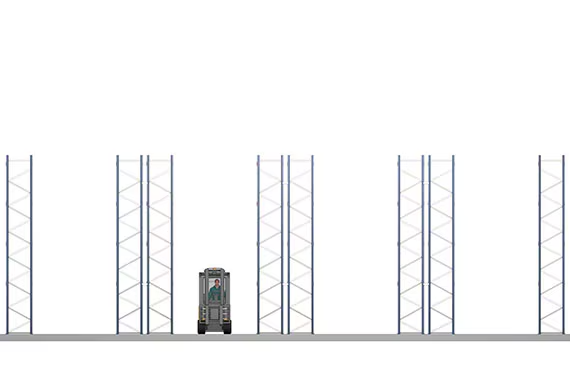

Single-deep pallet racks

Double-deep pallet racking

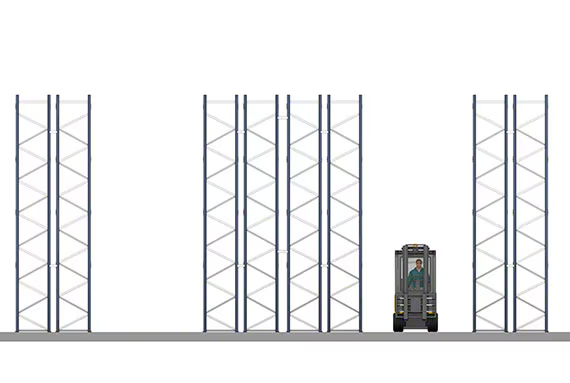

Narrow aisle pallet racking

Mobile pallet racking

Pallet racks with picking shelves

FAQS

Characteristics of Selective Pallet Racking

A selective pallet racking system is a popular storage solution that allows easy access to every pallet. It is designed to maximize storage capacity while offering direct access to each pallet, making it ideal for warehouses in Saudi Arabia, including Dammam and Riyadh, and across the UAE, Dubai, and Qatar.

The key features of a selective storage racking system include its adjustable height, customizable depth, and compatibility with different pallet sizes. These features make it a flexible solution for warehouses in locations like Tel Aviv, Jerusalem, and Kuwait, providing efficient use of space.

Selective racking allows warehouses in Saudi Arabia and UAE to optimize vertical and horizontal space. The system’s design reduces aisle width requirements, enabling better storage of goods without compromising accessibility.

Selective pallet racking systems are made of high-quality steel, ensuring they are strong, durable, and can handle heavy loads. This durability is especially important for large-scale warehouses in cities like Riyadh and Dammam, where long-term investments in storage solutions are critical.

- Yes, selective racking systems are highly customizable. In Saudi Arabia, Dubai, and Qatar, businesses can tailor the racking height, width, and depth to fit their specific storage needs, providing the flexibility required for diverse inventory types.

Maintaining a selective pallet racking system involves regular inspections for damage, ensuring proper load distribution, and keeping the racking clean. Maintenance is straightforward, ensuring longevity for warehouses in Riyadh, Dammam, and across the GCC.

Safety features include sturdy uprights, beams with locking mechanisms, and the ability to install safety barriers. These features are important for preventing accidents in warehouses in cities like Dubai and Tel Aviv, ensuring safe storage practices.

Selective racking systems enhance organization by offering clear, easy-to-access storage locations for each pallet. This organization improves efficiency in operations in places like Kuwait and Jerusalem, ensuring faster retrieval times.

Selective storage racking systems are best for storing a wide range of products, from small items to large pallets, making them ideal for warehouses in Riyadh, UAE, and Qatar that store varying product types.

While selective pallet racking maximizes storage, it is not designed for extremely high-density storage needs like other racking systems (e.g., drive-in). It is best for warehouses in cities like Dammam, Riyadh, and Dubai with moderate to high-density storage requirements.

Uses of Selective Pallet Racking

The primary use of selective pallet racking is to store pallets in a way that provides direct access to each one. This system is ideal for warehouses in Saudi Arabia, Dammam, and Riyadh, where quick retrieval of inventory is crucial.

In e-commerce warehouses in Dubai, UAE, and Qatar, selective pallet racking is used to store products for easy picking and restocking, ensuring fast order fulfillment and streamlined operations.

Yes, selective pallet racking systems can be used for cold storage facilities in places like Riyadh and Dammam, allowing temperature-sensitive products to be stored efficiently while maintaining direct access.

Selective storage racking systems are commonly used in retail warehouses across Tel Aviv and Jerusalem to organize products in a way that allows easy and fast access to inventory, reducing pick times.

Industries like food distribution, automotive, pharmaceuticals, and manufacturing benefit from selective pallet racking in locations such as UAE, Saudi Arabia, and Qatar, as it allows for better inventory management and accessibility.

Selective racking simplifies inventory management by providing direct access to each pallet. This is particularly useful in Saudi Arabia and Dubai, where fast and accurate stocktaking is crucial.

Yes, in manufacturing plants across Riyadh, Dammam, and other cities in the GCC, selective pallet racking helps store raw materials and finished goods, ensuring organized workflows and easy access to materials.

For high-turnover businesses in cities like Kuwait and Qatar, selective storage racking ensures that products are easily accessible for quick turnover, reducing the time it takes to replenish stock.

Yes, selective pallet racking is versatile and can be used in warehouses of all sizes, making it a practical choice for businesses in locations such as Riyadh, Tel Aviv, and Dammam.

Selective pallet racking systems help reduce waste by maximizing storage space and reducing the need for additional shelving or storage units, making them an eco-friendly solution for warehouses in Saudi Arabia, Dubai, and Qatar.

About Your Supplier Nanjing Suhong Intelligent Storage Equipment

Absolutely. Suhong offers a complimentary technical visit where our storage solutions experts collaborate with clients to understand their requirements and goods flow, creating a customized warehouse layout tailored to their logistical needs.

We are a professional manufacturer of metal products and have our own factory.

The raw material is high-quality low-carbon steel q235.

Yes, we do custom products and projects.

Yes, we can make the best suitable design for you but do need to know the details.

Yes. Samples could be provided.

Plastic banding or Stretch film wrapped ensures safe delivery.

TT or L/C at sight, Trade Assurance, etc.

Yes. We will send you information and photos at the different production stages of your order. You will get the latest information in time.

It depends on the order quantity and types. In general, within 4-6 weeks, for an ordinary order quantity.

We take full responsibility for any manufacturing defect, would either refund or reship good products to you.

RELATED PRODUCTS

WIRE MESH DECKING

VNA RACK :VERY NARROW AISLE RACKING

RACK UPRIGHT PROTECTOR

DRIVE-IN RACKING

PUSH-BACK RACKING

PALLET FLOW RACKING

SHUTTLE RACKING