When determining the appropriate racking solution for your warehouse, it’s crucial to consider several key elements. Whether you are unsure of your specific needs or have defined parameters, the following guidelines will help you provide the necessary information for a precise and effective racking system design.

A. If You Are Not Sure About the Specific Parameters of Your Required Rack

To assist in designing the best racking solution, please provide the following information:

Warehouse Floor Drawing:

- A detailed layout of your warehouse floor, including dimensions, existing structures, and any potential obstacles.

Pallet Dimensions and Weight:

- The length, width, and height of the pallets with goods.

- The weight capacity of a single loaded pallet.

Forklift Channel and Lifting Height:

- The size of the forklift operating channel.

- The maximum lifting height of your forklift.

Requirements for Picking and Placing Goods:

- Any specific needs for how goods are to be picked and placed, such as access frequency, handling type (manual or automated), and ergonomic considerations.

B. If You Have the Target Size Parameters of Your Required Rack

For those who have specific racking requirements, please provide the following details:

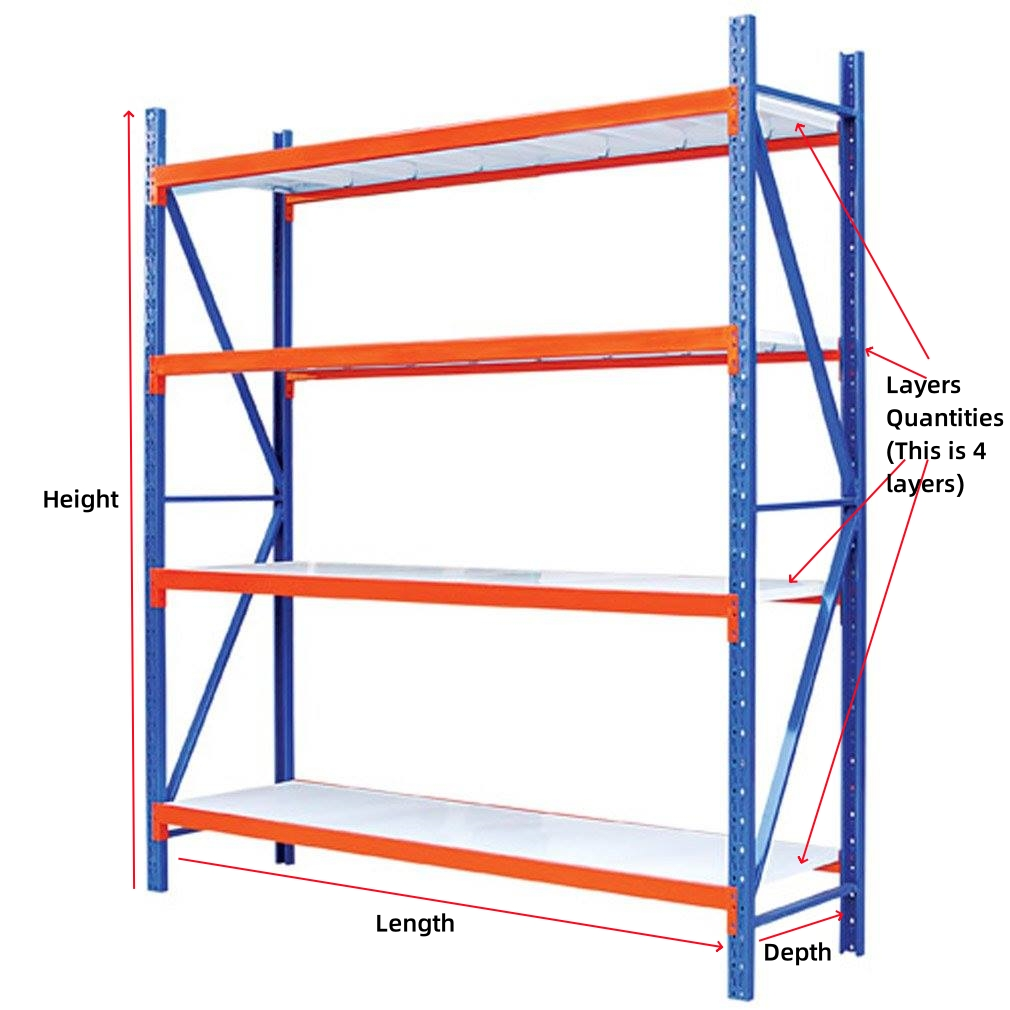

Rack Dimensions:

- The length, depth, and height of the rack.

Number of Rack Layers:

- The total number of layers or levels within the rack.

Load-Bearing Capacity of Each Layer:

- The weight capacity that each layer of the rack needs to support.

A number of Main Racks and Subracks:

- The total number of main racks and sub racks required.

- Optionally, you can send a layout diagram or warehouse plan. Our technician team can design a customized solution for you at no additional cost.

Additional Considerations for a Comprehensive Racking Solution

- Material and Finish:

- Specifications for the materials (e.g., steel, aluminum) and any special finishes (e.g., powder coating, galvanized) for durability and protection.

- Safety Features:

- Inclusion of safety features such as rack protectors, anti-collapse mesh, and safety barriers.

- Adjustability:

- Whether you require adjustable beams for flexibility in storage configurations.

- Compliance:

- Ensuring the racking system complies with local building codes and safety regulations.

Conclusion

By providing detailed information, you can ensure that your racking system is tailored to your specific needs, optimizing storage space and enhancing operational efficiency. This professional approach not only demonstrates expertise but also helps build trust with clients, showing a commitment to delivering high-quality, customized storage solutions.

For further assistance or to discuss your requirements in detail, please feel free to contact our technical team. We are here to help you design the most effective and efficient racking system for your warehouse needs.