Pallet Flow Racking Systems

Our Pallet Flow Racking Systems are designed to optimize warehouse storage by utilizing gravity for efficient stock rotation. These systems use inclined tracks and rollers, allowing pallets to flow smoothly from the loading side to the picking side. Ideal for FIFO (First In, First Out) operations, our flow racks ensure fast and easy access to inventory, reducing labor costs and improving throughput. Perfect for warehouses in Saudi Arabia and beyond, these racking solutions are durable, space-saving, and help streamline inventory management. Whether you need pallet gravity flow racks or roller pallet racking systems, we have a solution for your business.

Pallet Flow Racking Systems for Efficient Warehouse Operations

Key Benefits of Pallet Flow Racking Systems:

- Maximized Space Utilization: Flow racks provide high-density storage, using vertical space to accommodate more products in less floor area.

- Improved Efficiency: Automatic product rotation with FIFO reduces handling time, improving picking and replenishment speed.

- Increased Product Safety: Gravity-powered flow racks minimize the risk of product damage caused by forklifts or manual handling.

- Reduced Labor Costs: With automated stock movement, employees spend less time on product handling, resulting in reduced labor costs.

- Enhanced Inventory Control: FIFO ensures accurate stock rotation, reducing the risk of stockouts or product spoilage.

Scalability: The system can be easily customized to fit warehouses of various sizes and industries in Saudi Arabia, UAE, Qatar, Kuwait, and more.

For businesses in regions like Riyadh, Dammam, Dubai, and Jerusalem, pallet flow racking offers an essential solution to optimize warehouse efficiency and increase operational capacity.

In addition to being very practical, with these racks, we’ve eliminated aisles and streamlined storage tasks

PALLET FLOW RACKING SYSTEM APPLICATIONS

Large-scale storage of high-turnover SKUs

Storage of perishable products

Interim warehousing between two working zones

Buffer management

Cold stores

HOW DOES A PALLET FLOW RACKING SYSTEM WORK?

Pallet storage

Pallet movement

Pallet removal

PALLET FLOW RACKING CONFIGURATIONS

With 2 working aisles (FIFO method)

With a single working aisle (LIFO method)

Flow channels for picking from pallets

Pick modules with pallet flow rack channels

Automated storage systems with pallet flow racking

Clad-rack warehouses with pallet flow racking

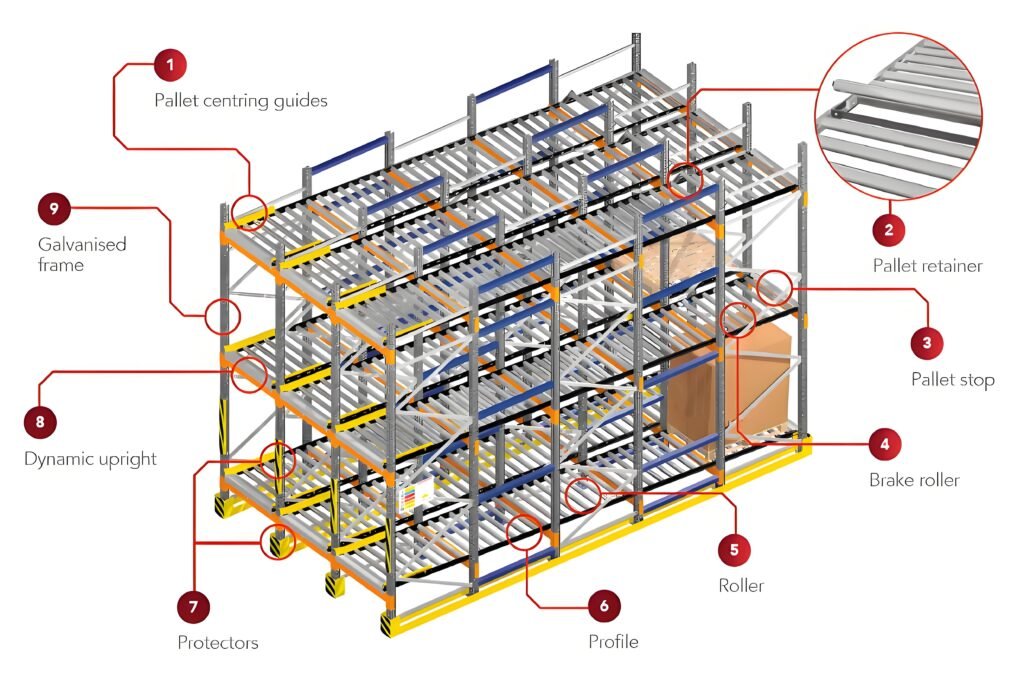

GRAVITY RACKING ACCESSORIES

PALLET RETAINERS

CHANNELS AT FLOOR-LEVEL FOR PALLET TRUCKS

SPLIT ROLLERS

HINGED CHANNELS

FAQS

Characteristics of Pallet Flow Racking

A Pallet Flow Racking system is a dynamic storage solution that uses gravity to move pallets through lanes. It ensures high-density storage and improves inventory turnover. Commonly used in Saudi Arabia, Dubai, and Qatar, this system is ideal for FIFO (First In, First Out) processes.

A Flow Rack System operates using rollers or wheels to allow pallets to move along an inclined track by gravity. It’s a highly efficient way to organize goods, commonly found in Dammam and Tel Aviv warehouses, offering quick and easy access.

Gravity Racking Systems, such as pallet flow racks, minimize manual labor and improve the speed of inventory management in locations like Kuwait and Riyadh. They optimize space and streamline operations by ensuring goods are automatically fed to the picking area.

FIFO Pallet Racking is a system that ensures the oldest products are used first. In regions like Saudi Arabia and Dubai, businesses use FIFO pallet flow racking systems to ensure compliance with industry standards and maintain product freshness.

Pallet Gravity Flow Racks are specifically designed to use gravity to move pallets, whereas other systems may rely on manual handling or mechanical equipment. This makes gravity racking more efficient, especially in warehouses in Tel Aviv and Qatar.

Yes, flow rack systems can be customized to fit various warehouse sizes and operational needs. Whether you’re in Riyadh, Dubai, or Dammam, these systems can be tailored to optimize storage and increase picking speed.

Pallet Flow Racking Systems are highly versatile and can handle different types of goods, such as perishables, packaged items, or bulk products. Businesses in Jerusalem and Kuwait often use these systems for various types of inventory.

Pallet Flow Racks can support varying weights depending on their design. In locations like UAE and Saudi Arabia, the capacity can range from lighter items to heavy-duty pallets, ensuring versatility for different industries.

Yes, Roller Pallet Racking Systems are easy to install and require minimal maintenance. These systems are commonly used in regions like Qatar and Dammam, offering fast and efficient storage solutions with minimal downtime during setup.

Pallet Flow Racking systems reduce the need for manual labor, allow quick access to products, and optimize warehouse space. Businesses in cities like Riyadh, Dubai, and Tel Aviv can see significant efficiency improvements, especially in high-demand warehouses.

Uses of Pallet Flow Racking

Pallet Flow Racking systems are used in various industries, including retail, food and beverage, pharmaceuticals, and e-commerce. These industries in Saudi Arabia, Qatar, and UAE rely on these systems for fast inventory turnover and efficient storage.

In a FIFO Pallet Racking system, older stock is pushed out before newer stock. This method is essential in industries like food storage in Dubai and Kuwait, where perishable goods must be used before their expiration date.

Yes, Pallet Flow Racks can be used in cold storage environments, including refrigerated warehouses in Saudi Arabia and UAE, thanks to their durable construction and ability to maintain product flow at low temperatures.

In Riyadh, businesses use pallet flow racks to store high-turnover items, such as beverages and electronics. These systems provide efficient stock rotation and ensure quick order fulfillment, improving overall logistics.

Yes, Pallet Flow Racking is ideal for high-density storage in warehouses across Saudi Arabia and Qatar. It allows for maximum storage in minimal space, making it perfect for industries that require high-volume storage like manufacturing.

With pallet flow racking systems, the pallets are automatically fed to the front of the system, improving picking speed. Businesses in Dubai, Tel Aviv, and Kuwait benefit from reduced labor and faster order fulfillment.

- Yes, Pallet Flow Racking systems are flexible and can be used in both large and small warehouses. In smaller spaces like those in Jerusalem and Dammam, these systems help maximize storage efficiency while maintaining easy access to products.

Pallet Flow Racking Systems can handle heavy items by using robust materials and roller tracks. In industrial warehouses in Riyadh and Qatar, these systems are utilized to store and move heavy machinery and parts.

Pallet Gravity Flow Racks are perfect for high-throughput environments where fast and efficient stock movement is necessary. These systems are widely used in UAE and Saudi Arabia, providing a steady flow of goods without requiring constant manual intervention.

In pharmaceutical warehouses in Dubai and Tel Aviv, FIFO Pallet Racking Systems ensure that medications are used within their expiration period. These systems provide an organized and regulated way to manage sensitive stock in time-sensitive environments.

About Your Supplier Nanjing Suhong Intelligent Storage Equipment

Absolutely. Suhong offers a complimentary technical visit where our storage solutions experts collaborate with clients to understand their requirements and goods flow, creating a customized warehouse layout tailored to their logistical needs.

We are a professional manufacturer of metal products and have our own factory.

The raw material is high-quality low-carbon steel q235.

Yes, we do custom products and projects.

Yes, we can make the best suitable design for you but do need to know the details.

Yes. Samples could be provided.

Plastic banding or Stretch film wrapped ensures safe delivery.

TT or L/C at sight, Trade Assurance, etc.

Yes. We will send you information and photos at the different production stages of your order. You will get the latest information in time.

It depends on the order quantity and types. In general, within 4-6 weeks, for an ordinary order quantity.

We take full responsibility for any manufacturing defect, would either refund or reship good products to you.

RELATED PRODUCTS

WIRE MESH DECKING

VNA RACK :VERY NARROW AISLE RACKING

RACK UPRIGHT PROTECTOR

DRIVE-IN RACKING

PUSH-BACK RACKING

PALLET FLOW RACKING

SHUTTLE RACKING