1- What Is Selective Pallet Racking?

Selective Pallet Racking is a pallet storage system that is suitable for storing goods of many categories.

2- What Is Selective Pallet Racking Used for?

Selective Pallet Racking gives you an excellent opportunity for your warehouse to fulfill storage needs at a very low price.

Selective Pallet Racking uses a rack structure to store products loaded on pallets with the help of a forklift.

3- How Does Selective Pallet Racking Work?

Selective Pallet Racking System consists of upright frames and load beams that give you 100% efficiency in selecting the stored product.

You can load/unload the products into the racks with the help of a forklift.

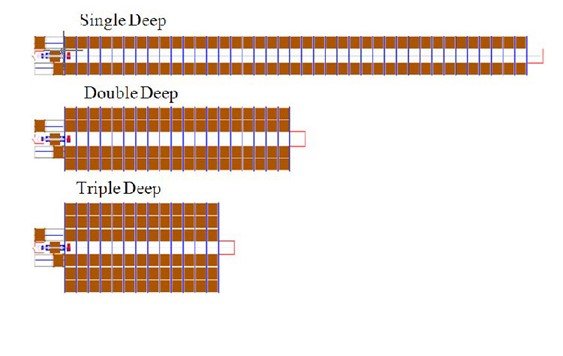

4- How Much Deep Can Selective Pallet Racking be Made?

Single deep,double deep,triple deep .

Any type of forklift can be used for loading and unloading the products in single deep Selective Pallet Racking, whereas double deep Selective Racking requires some special forklifts like an articulated forklift or reach truck.

5- How Much Weight Can Selective Pallet Racks Hold?

Selective Pallet Racking is a kind of heavy-duty racking system which is extremely flexible and has a high utilization rate.

The load requirements are determined by measuring where the beams are installed in each rack; if you move beams up or down, the load capacity changes.

In standard Selective Pallet Racking, each layer can hold a weight up to 4000kg.

6- How Products are Loaded/Unloaded In Selective Pallet Racking?

You can load/unload the products in Selective Pallet Racking with the help of a forklift.

7- What are The Components of Selective Pallet Racking?

Selective Pallet Racking has the following components.

-

- Load Beams: Load beams are also called step beams or box beams, which are used to support the loaded products in Selective Racking.

-

- Upright frames: Upright frames are also called upright columns or uprights. Load beams are attached in between the uprights.

-

- Diagonal braces and horizontal braces: These braces are welded between the upright frames to make the system of Selective Racking.

-

- Wire Decking: Wire decking can be used in Selective Pallet Racking to prevent the loaded products from falling down the system.

-

- Footplates: Footplates are also known as base plates, or footpads are at the base of upright frames to provide stability to the Selective Racking System.

Row Spacers: If you want to arrange uprights in back-to-back rows, then row spacers are used. They are made between the adjacent columns to ensure that the rows are straight.

8- How Tall Is The Selective Pallet Racking?

Selective Pallet Racking comes in a variety of heights, beam lengths, and weight capacities.

The height of Selective Pallet Racking can be made according to your usage, i.e., it depends on the quantity of your products.

9- What Is The Aisle In Selective Pallet Racking?

Aisle is a space between Selective Pallet Racking where you can move freely or drive the forklift easily.

The forklift operators use the aisle space to load/unload the products in Selective Pallet Racking.

The aisle space should be such that you can easily drive the forklift in between the lanes of Selective Pallet Racking.

Usually, the aisle space is about 2m to 3m between the lanes of Selective Racking.

10- What Is a Bay In Selective Pallet Racking?

Selective Pallet Racking consists of Upright steel frames and load beams that hold the stored products into the system.The space between the upright steel frames where load beams are attached is called the bay of Selective Pallet Racking.

11- What Are Beams In Selective Pallet Racking?

Load beams also called the step beams or the box beams, are connected between the two upright frames of Selective Pallet Racking System. These beams are used to support the loaded products in Selective Pallet Racking.

12- Can You Adjust The Beams In Selective Pallet Racking?

The beams of Selective Pallet Racking are connected between the two vertical upright frames that help to hold products in the system.

Selective Pallet Racking has a composite structure, where you can adjust the height of beams arbitrarily.

The products are of any height, so when placing the products on the beams, space between beams should be considered.

This feature allows you to load the product of any height.

13- What Is The Function of The Span Beam In Selective Pallet Racking?

Selective Pallet Racking beams are used to hold your pallet-loaded products onto the system.

Sometimes the size of pallets is too small that you cannot place these pallets on both sides of the corresponding beams.

To avoid this difficulty, you can place span beams on the beams connected between upright frames that support the small pallets loaded in Selective Pallet Racking.

Adding span beams to the system increases your product’s safety.

13- What Is The Function of Back Mesh In Selective Pallet Racking?

When you load the product from the front side of the Selective Pallet Racking, the product may fall from the backside of the system.

There must also be some security measures from the backside of the Selective Pallet Racking to prevent product damage.

The back mesh can be added to the Selective Pallet Racking that prevents the products from falling from the backward.

14- What Type of Pallets Can Be Used In Selective Pallet Racking?

You can use any type of pallet in a Selective Pallet Racking System.

Two-way entry pallets or four-way entry pallets are suitable for storing products in Selective Pallet Racking.

You can use wooden pallets, plastic pallets, metal pallets, and cardboard pallets.

Plastic pallets can bear weight up to 680 kg, whereas; wooden pallets can bear weight up to 1500 kg.

15- What are The Advantages of Selective Pallet Racking?

-

- The height of Selective Pallet Racking can be made according to your usage, i.e., it depends on the number of your products.

-

- Selective Pallet Racking is a heavy-duty racking system that is extremely flexible and has a high utilization rate.

-

- Selective Pallet Racking has direct access to every stored product.

-

- Selective Pallet Racking is suitable for storing a variety of products.

-

- You do not need to enter in the Selective Pallet Racking to load/unload the products.

-

- You can store products on plywood, pallets, or additional wireframes in Selective Pallet Racking.

-

- Every stored pallet is in a different position and does not affect the other stored pallets.

-

- Selective Pallet Racking provides you a high storage density.

-

- You can easily install and re-configure the Selective Pallet Racking.

-

- You can store bottom-level products on the floor that lowers the structure cost.

-

- More than one forklift can load/unload the products in Selective Pallet Racking’s aisle, giving a significant impact on the efficiency of work.

-

- Selective Pallet Racking is the most affordable form of warehouse storage solution.

16- What are The Disadvantages of Selective Pallet Racking?

-

- Selective Pallet Racking requires a large number of aisles for loading/unloading the products.

-

- Because a large number of aisles are required for loading/unloading the products, you need overall more storage space for storing the same amount of product.

-

- You will need more time for loading/unloading in Selective Pallet Racking as the same type of product would need to store on different racks.

-

- If you need to load/unload products in a short time, you will need a large number of forklifts and forklift operators to complete the task, thus increasing the cost.

17- How Far Should a Selective Pallet Racking Be From The Wall?

Selective Pallet Racking can be made such that the back of the system has wall support for the stored products.

This wall support prevents the stored product from falling down from the back.

You can design the Selective Pallet Racking according to your storage needs, but a standard Selective Pallet Racking can be designed about 1 m/3 foot from the walls of your storage area.

18- What Types of Forklifts Can Be Used In Selective Pallet Racking?

Selective Pallet Racking has aisles in which the forklifts operate for loading and unloading the products. The type of forklift depends on aisle width.

If you have designed a Selective Pallet Racking aisle width about 4m to 5m, then you can use a counterbalance forklift that lifts the product up to 8m high.

Selective Pallet Racking having aisle width of about 2m to 3m can make use of reach trucks that can lift the products up to 11m high.

If the aisle width of Selective Pallet Racking is about 1m to 2m, then you can also use articulated forklifts that can lift up to 12m high.

You can also use telehandler forklifts in Selective Pallet Racking that can lift your product up to 17m high.

19- Do Selective Pallet Racking Uses a Special Forklift To Load/Unload The Products?

No, Selective Pallet Racking does not use special forklifts for loading and unloading the products.

You can use any type of forklift depending on the width of Selective Pallet Racking aisles.

Counterbalance forklifts, Reach trucks, and Articulated forklifts are some of the most useable forklifts in Selective Pallet Racking.

20- Can You Load/Unload The Products In Selective Pallet Racking Without a Forklift?

Yes, a Selective Pallet Racking can be used without a forklift.

As Selective Pallet Racking provides direct access to every stored product, you can load and unload the products by using your hands.

21- What Is The Storage Floor Usage In Selective Pallet Racking?

The storage floor can also be referred to as the storing area of the Selective Pallet Racking.

You can store your products on the bottom of the Selective Pallet Racking, i.e., on the storage floor.

22- Why Does Selective Pallet Racking Need To Be Bolted To Floor?

A warehouse is a high-risk environment in which an incorrectly installed Selective Pallet Racking will leave your products at risk of damage and risk of injury of the workers.

As loading and unloading are carried out with the help of a forklift, there is always a risk of a forklift colliding with the Selective Pallet Racking.

Bolting to the floor always keep the Selective Pallet Racking sturdy in the event of a natural disaster, such as an earthquake that reduces the risk of any damage to the products or workers injury.

23- What Is The Delivery Time of Selective Pallet Racking?

Selective Pallet Racking can be ordered from different racking manufacturer companies around the world that have different delivery times.

Chinese racking companies are considered to be the world’s best racking manufacturer for your warehouse storage needs having a reasonable price per pallet and the fastest delivery time.

Nanjing Suhong Intelligent Storage can deliver your order within 10 to 15 days for regular pallet racking.

24- How To Install Selective Pallet Racking?

Selective Pallet Racking consists of upright steel frames, beams, diagonal braces, horizontal braces, footplates, and dynamic profiles that are connected together to form the structure. You should install the Selective Pallet Racking from experts.

25- How Long Is The Selective Pallet Racking Warranty?

Nanjing Suhong Intelligent Storage provides a long warranty of ten years for all types of racking.

26- How To Maintain a Selective Pallet Racking?

Selective Pallet Racking is one of the acknowledged ways to enhance your storage space, but they also require timely maintenance to make sure that they continue to work properly.

Following are the points that describe maintaining the Selective Pallet Racking.

-

- Capacity placards or beam capacity labels must be installed on each load beam that provides load weight, load size, and rack configuration the rack was designed for.

-

- During the installation and use of Selective Pallet Racking, you should avoid climbing on the racks.

-

- Warning lights can be added to the upright frames to keep the Selective Pallet Racking visible and avoid collision.

-

- The aisle space should be such that you can easily drive the forklift in between the lanes of Selective Pallet Racking.

-

- You should load products in such a way that there are about 6 inches of space between the top of the load and beam.

-

- There should be a minimum of 4 inches of space on both sides of the stored pallet.

-

- You should avoid overloading the Selective Pallet Racking that may cause rack collapse that not only damages the product but also puts your employees at risk for injury.

-

- In case of damage to the Selective Pallet Racking, you must call an expert.

27- How Often Should Selective pallet Racking Be Inspected?

At least one racking inspection must be carried out every 12 months.