Shuttle Pallet Racking System

Shuttle Pallet Racking System – Maximize Your Warehouse Efficiency

Key Benefits of the Shuttle Pallet Racking System

- Maximized Storage Density: The shuttle system allows you to store more pallets in less space, increasing overall storage capacity and reducing the need for excessive warehouse floor area.

- Enhanced Efficiency: Automated pallet shuttles improve picking and retrieval speed, reducing operational downtime and enhancing productivity within the warehouse.

- Improved Safety: With minimal manual handling required, the shuttle system reduces the risk of worker injuries and optimizes safety within the warehouse environment.

- Adaptability: Our shuttle pallet racking systems are designed to adapt to various sizes and types of pallets, making them versatile for different industries and warehouse layouts.

- Cost-Effective: The shuttle system minimizes operational costs by optimizing storage space and streamlining labor, saving both time and money.

- Reliable and Durable: Manufactured to meet high-quality standards, our shuttle pallet systems provide long-term, dependable performance, making them a wise investment for any warehouse.

- Maximized Storage Density: The shuttle system allows you to store more pallets in less space, increasing overall storage capacity and reducing the need for excessive warehouse floor area.

In addition to being very practical, with these racks, we’ve eliminated aisles and streamlined storage tasks

| Parameter | Standard Room Temperature Version | Standard Cold Storage Version | Customized Version (Normal Temperature) | Customized Version (Cold Storage) | Customized Version (Network Version) |

| Max Load | 1.5T | Network modules can be added to each version to customize the network version | |||

| Travel Motor | 48VDC 750W 3000rpm brushless motor (High quality made in China Leadshine,Cold storage version is dedicated to low temperature) | ||||

| Travel Servo Driver | Brushless servo driver (High quality made in China Leadshine,Cold storage version is dedicated to low temperature) | ||||

| Speed | 1.2 m/s (No load)0.9 m/s (full load) | ||||

| Speed Control Mode | Independent R & D control core, ensure full range constant speed; Put an end to the damage caused by rapid deceleration to the shelf, and effectively ensure the shelf life | ||||

| Operating Ambient Temperature | -10°C to 50°C | -25°C to 50°C | -10°C to 50°C | -25°C to 50°C | |

| Humidity of Working Environment | 10% to 85% (non-condensing) | ||||

| Suitable for Standard Pallet Sizes | Pallet fork direction 1200mm | Pallet fork direction 1100mm-1500mm and above | |||

| Track Adaptation | 163mm | 130mm-163mm | |||

| Space Between Cargo | 5 to 25cm adjustable, set via radio controller | ||||

| Jacking Motor | 8VDC 750W 3000rpm brushless motor (High quality made in China Leadshine) | ||||

| Jacking Motor Servo Driver | Brushless servo driver (High quality made in China Leadshine) | ||||

| Jacking Height | 45mm | ||||

| Lithium Battery | 48V30AH / 1000 times of charging and discharging; High quality lithium iron phosphate battery made in China,Cold storage version is dedicated to low temperature; It takes 3-4 hours to charge to 100% at normal temperature | ||||

| Shuttle Service Hours | Operating time at full power ≥8Hours | ||||

| Operating Noise | ≤70db | ||||

| Network Interface | None | Ethernet Hardware Interface + TCP communication | |||

| Shuttle Control Mode | Radio controller | Radio controller/WCS | |||

| Remote Control Performance | The button type radio controller. Developed on the basis of imported MCU; it has stronger functions, higher security, and more friendly operation. It can be used for 1 week at full power; The operating frequency is 433MHz, the communication distance is at least 200m, and the 2.4-inch LCD color display is clearer. | ||||

| Operation Fault Prompt Mode | Standard problem base, easy to locate and handle problems | ||||

| Positioning Mode | Traveling positioning: laser, tray positioning: Laser + photoelectric, jacking positioning: proximity switch (sick) | ||||

| Shuttle Control Core | Control core independently developed based on imported MCU (Italian ST) | ||||

| Painting Color | Red, light grass green, lemon yellow, sky blue, deep sea blue, etc. | ||||

RADIO SHUTTLE RACKING APPLICATIONS

Radio shuttle racking systems are ideal for high-density storage applications, offering increased storage capacity while reducing the need for manual labor. Commonly used in industries such as food and beverage, pharmaceuticals, and logistics, these systems are perfect for handling large volumes of pallets efficiently. Radio shuttle racking is especially beneficial for warehouses in regions like Saudi Arabia, UAE, and Qatar.

Food and Beverage Industry

For businesses needing cold storage, the Shuttle Racking system offers high-density storage in temperature-controlled environments, efficiently managing large volumes of perishable goods in both FIFO and LIFO modes.

Automotive Industry

With varied and bulky components, automotive warehouses can benefit from the Shuttle Racking system’s ability to handle heavy loads and optimize storage space, speeding up the retrieval of parts and enhancing overall efficiency.

FAQS

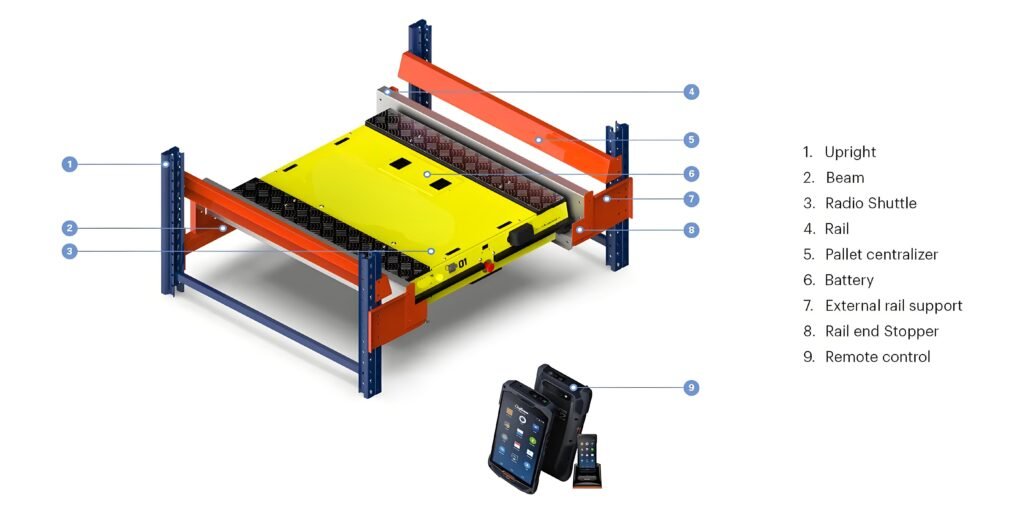

The Characteristics of Shuttle Racking

Shuttle pallet racking is an advanced storage solution that uses automated shuttles to move pallets within a racking system. It helps improve efficiency by automating the process of storing and retrieving goods in warehouses.

A pallet shuttle racking system uses electric shuttles to move pallets into and out of the storage lanes. This system reduces manual labor and enhances storage density, making it ideal for high-density storage in warehouses.

A shuttle racking system is characterized by its ability to store pallets at high density, automated retrieval and placement, and high-speed operation. It is a space-saving solution that optimizes warehouse space.

Yes, shuttle racking systems can handle various pallet sizes and weights. The system is adaptable, making it suitable for a wide range of warehouse requirements.

Yes, the shuttle pallet racking system is highly scalable. It can be expanded or customized to fit the growing needs of businesses, especially in large warehouses in Saudi Arabia, UAE, and Qatar.

The primary benefits include increased storage capacity, reduced labor costs, faster inventory management, and minimized human error. It’s ideal for high-volume operations like those in Riyadh, Dammam, and Dubai.

Shuttle pallet racking systems are designed with safety in mind, featuring secure pallet placement, reduced manual handling, and controlled movement, ensuring a safe warehouse environment.

Shuttle racking systems are typically made from high-quality steel for durability and strength. This makes them reliable and capable of supporting heavy loads in warehouses across Saudi Arabia, Kuwait, and Tel Aviv.

Yes, like all automated systems, the shuttle racking system requires regular maintenance to ensure smooth operation. This includes checking the shuttle motors, tracks, and control systems.

- By automating the storage and retrieval of pallets, the shuttle racking system significantly reduces the time spent on manual labor, increasing warehouse efficiency and allowing for more products to be stored in less space.

The Uses of Shuttle Racking

Industries such as food and beverage, retail, manufacturing, and logistics benefit from shuttle pallet racking systems due to their high efficiency and space-saving capabilities, especially in Saudi Arabia, UAE, and Qatar.

Yes, shuttle racking systems are commonly used in cold storage facilities in regions like Riyadh and Dubai, where they can help manage temperature-sensitive goods while maximizing storage space.

The shuttle racking system improves storage by increasing the storage density, enabling warehouses to store more products in the same space, making it ideal for large facilities in Dammam, Tel Aviv, and Kuwait.

Yes, shuttle pallet systems can be integrated into multi-level racking structures to maximize vertical storage, which is particularly useful in large warehouse operations in Saudi Arabia and Dubai.

Absolutely. Shuttle racking systems are equipped with advanced control systems that allow for real-time inventory management, making them ideal for businesses in Qatar and the UAE that require precise and efficient stock handling.

Shuttle racking systems are versatile and can store a variety of products, including heavy, bulky, and standard-sized pallets, making them perfect for warehouses in Riyadh, Dammam, and Jerusalem.

Yes, shuttle pallet systems support both FIFO (First In, First Out) and LIFO (Last In, First Out) storage methods, providing flexibility for warehouses in Tel Aviv, Riyadh, and Dubai, depending on inventory needs.

By automating the storage and retrieval processes, the shuttle racking system reduces the need for manual labor, leading to significant savings on operational costs in countries like Saudi Arabia and Qatar.

Yes, shuttle racking systems are particularly effective in smaller warehouse spaces, maximizing the available storage area, making them ideal for urban warehouses in locations like Dubai and Kuwait.

The shuttle racking system is designed to handle high throughput during peak seasons, ensuring that products are efficiently stored and retrieved, which is particularly useful in busy retail environments in Saudi Arabia and the UAE.

PALLET SHUTTLE TECHNICAL CHARACTERISTICS

Each shuttle can support up to 1,500 kg.

The Pallet Shuttle car can reach a maximum speed of 90 m/min unloaded and 45 m/min loaded.

The shuttle platform lifts the pallet in approximately 2 seconds.

Yes. On the one hand, there are two types of shuttles based on the operating temperature: those that work at ambient temperature (from +5 °C to +45 °C) and those that operate at refrigerated and freezing temperatures (from -30 °C to +5 °C). Shuttles designed to operate in cold environments come equipped with electronic components that are protected and heated to prevent damage.

On the other hand, each type of shuttle comes in three sizes, adapted to the most common pallet measurements. In each configuration, the front measurement of the shuttle is the same, given that in Pallet Shuttle systems, pallets are handled on the wider side (1,200 mm). What varies is their depth, with each configuration corresponding to a different pallet depth measurement (800, 1,000 or 1,200 mm).

The Pallet Shuttle’s lithium batteries provide an autonomy of up to 10 hours at full performance, depending on the temperature and load conditions.

About Your Supplier Nanjing Suhong Intelligent Storage Equipment

Absolutely. Suhong offers a complimentary technical visit where our storage solutions experts collaborate with clients to understand their requirements and goods flow, creating a customized warehouse layout tailored to their logistical needs.

We are a professional manufacturer of metal products and have our own factory.

The raw material is high-quality low-carbon steel q235.

Yes, we do custom products and projects.

Yes, we can make the best suitable design for you but do need to know the details.

Yes. Samples could be provided.

Plastic banding or Stretch film wrapped ensures safe delivery.

TT or L/C at sight, Trade Assurance, etc.

Yes. We will send you information and photos at the different production stages of your order. You will get the latest information in time.

It depends on the order quantity and types. In general, within 4-6 weeks, for an ordinary order quantity.

We take full responsibility for any manufacturing defect, would either refund or reship good products to you.

RELATED PRODUCTS

WIRE MESH DECKING

VNA RACK :VERY NARROW AISLE RACKING

RACK UPRIGHT PROTECTOR

DRIVE-IN RACKING

PUSH-BACK RACKING

PALLET FLOW RACKING

SHUTTLE RACKING