1. What is a Drive-in Rack?

The drive-in rack is a pallet racking system. It is based on the LIFO (Last In, First Out) inventory management.

It provides high-density storage. It means that you can store a large volume of products in less space.

It is the best solution to store products that have a fast turnover, uniformity, and long shelf-life.

There is only one open side of the drive-in rack to place or get the pallets/products.

It provides 75% more usage of available space than other storage systems.

Drive-in rack reduces the pathways (aisles), which increases the usage of available space.

A drive-in rack has the following properties:

- Support rails are used to store pallets.

- A lift truck can get the pallets that are most recently loaded into the rack at first.

- A floor-mounted guide rail is also a part of drive-in rack systems. It helps in reducing the frame damage.

2. What are the Applications of the Drive-in Rack System?

A drive-in rack system can be used for the following purposes:

- You can use drive-in rack systems to store products with long expiration dates.

- A drive-in rack system can also be used to store large products that require only a one-time move.

- You can store cooler or freezer items in the drive-in rack.

- Fragile products are also stored in the drive-in rack system.

- Almost all the products that cannot be stored in block stacks can be stored using a drive-in rack.

- Expensive storage items can be stored using a drive-in rack.

- Drive-in rack can be used in revenue warehousing.

- If you have slow-moving products, a drive-in rack is the best choice.

If you have limited space to store pallets, a drive-in rack can help you a lot.

3. What are the Dimensions of a Drive-in Rack?

Drive-in racks are available in dimensions according to your needs.

The average width of a pallet is 2.5 to 3.5 feet.

The maximum height of upright is 11.85 m.

The total height and width of the pallet are seen to adjust the other dimensions of a drive-in rack.

The dimensions are as follows:

- Level to level height

- Pallet width

- Pallet Height

- The total height of a level

- Arms width

- Clear between upright frames

- Center to the center area of upright frames

4. Which Inventory Management Flow Does the Drive-in Rack Support?

Drive-in rack supports Last In First Out(LIFO) Inventory management system.

The Drive-in rack has only a single entry/exit point. Therefore, you can get the last item stored at first.

As you can see in the image shown above, the pallets stored at last is being retrieved at first.

This is because you can only retrieve pallets from a single side. The other end of the drive-in rack is closed.

5. Can You Combine More Racks with the Drive-in Rack System?

Yes, it is possible to combine more racks with a drive-in rack system as per your requirement.

It is also possible to order additional components to attach to the drive-in rack.

Extending the rack by combining them with other pallet racks can be easily done.

6. Which Type of Products Can Be Stored Using Drive in Rack System?

A drive-in rack can be used for the following purposes:

- Drive-in rack systems are used to store products with long expiration dates.

- A drive-in rack system can also be used to store large products that require only a one-time move.

- Cooler or freezer items can also be stored in the drive-in rack.

- Fragile products are also stored in the drive-in rack system.

- Almost all the products that cannot be stored in block stacks can be stored using a drive-in rack.

- Expensive storage items can be stored using a drive-in rack.

- The drive-in rack is used for revenue warehousing.

- If you have slow-moving products, a drive-in rack is the best choice.

7. What is the Difference between Drive-Thru and Drive-in Rack?

The Drive-in rack is based on the Last In First Out(LIFO) inventory management flow.

There is only a single point that can be used to place or get the pallets from the drive-in rack.

Forklifts can only enter from one side of the drive-in rack.

Whereas, drive-thru rack is based on the First In First Out(FIFO) inventory management flow.

You can load the pallets from one side and retrieve them from the other side of the drive-thru rack.

Forklifts can enter from both sides in a drive-thru rack.

8.What are the Advantages of Using Drive in Rack?

Drive-in rack has the following advantages:

- Drive-in rack improves utilization of warehouses because it leaves no special channel for forklift.

- You can arrange more inventory locations in a drive-in rack.

- Drive-in rack can adapt to various types of pallets.

- Drive-in rack can meet different storage size requirements. This is because you can adjust the beam height according to your cargo size.

- The drive-in rack provides good strength of the shelf structure.

- The cost of the drive-in rack is quite low compared to other pallet racks.

- Drive-in rack saves time during storing or retrieving goods.

- Drive-in rack provides high-density storage.

- Drive-in rack maximizes square footage in your warehouse.

- The drive-in rack provides better control over entry and exit.

9. What are the Disadvantages of Drive-in Rack?

The disadvantages of the drive-in rack are as follows:

- The drive-in rack is not suitable for small batches or varieties of products.

- In a drive-in rack, the dimensions of the forklift must match the dimensions of the rack.

- Products can be misplaced if the arrangement is not done properly.

- The driver of the forklift should be more careful because he has to enter into the drive-in rack.

- The selectivity of pallets is limited in a drive-in rack system.

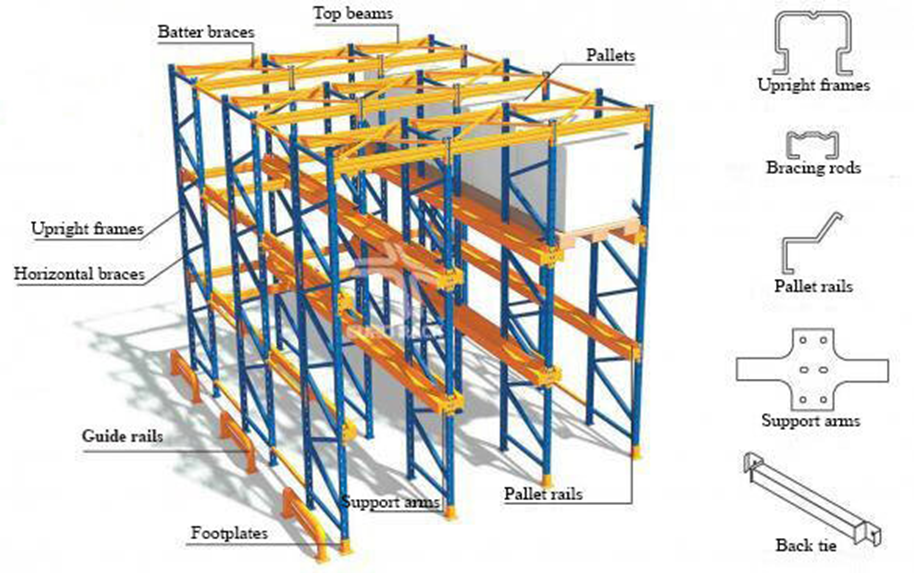

10. What are the Basic Components of a Drive-in Rack?

Drive-in Rack Structure

The basic components of a drive-in rack are as follows:

- Upright Frame: Bear for the entire drive-in rack system.

- Horizontal Brace: Divider of the upright frames.

- Top Beam: Connection between two upright frames.

- Batter Brace: Support between two top beams that connect upright frames.

- Footplate: Keep the drive-in rack in a steady position by connecting the upright frames to the floor.

- Guard Rail: It protects the drive-in rack from collisions.

- Support Arm: It bears the weight of the pallets by dispersing their energy to the upright frames.

- Pallet Rail: These rails provide support to keep the pallet stable.

11. Is Drive in Rack System Adjustable?

Yes, the drive-in rack is adjustable. You can adjust a drive-in rack according to your pallet size requirements.

It is because the upright pitch can be set at a 50mm or 75mm pitch.

This means the adjustable hole distance makes its height adjustable.

There are different things you can adjust in a drive-in rack.

You can also set the placement of support arms, upright frames as well as pallet rails.

You will first adjust the placement of support arms and then the rails according to it.

12. How Does Drive in Rack Work?

At first, the drive-in rack is assembled and installed properly.

A drive-in rack works in the following sequence:

- The product is placed on the pallet and then loaded on the forklift.

- The forklift enters the drive-in rack from the open side.

- The support rails of the drive-in rack are used to place the pallets on it.

- After placing the pallet in the drive-in rack, a forklift is moved backward to get out from the rack.

- When you require a pallet from the drive-in rack, the forklift again enters the rack.

- The forklift holds the required pallet by sliding it backward on the support rails.

- The forklift exits the drive-in rack from the same point by reversing itself.

13. What are the Things to Consider before Buying a Drive-In Rack?

Before buying a drive-in rack, you should consider the following aspects:

- Your Product’s Type: Which type of products you are planning to store in the drive-in rack. If these are a group of similar/seasonal products you should buy the drive-in rack.

- Your Product’s Size: If there are no variations in the size of your products then a drive-in rack is the best choice.

- Your Product’s Turnaround Time: If you have a quick turnaround time, a drive-in rack is a good choice.

- The Quality of Material: You should assure that the quality of materials in the drive-in rack is good.

- Experienced Seller: You should also look out for the best-sellers who are experienced in making drive-in racks.

- Availability of Professionals: You should also check if you can have experienced professionals who can install the drive-in rack properly.

14. How Should a Drive-in Rack be Packed?

All parts of the drive-in rack should be covered by plastic film.

It is because the impacts of damage can be transformed into plastic film if anything happens to the drive-in rack.

You can save the state of a drive-in rack during long transportation by following steps:

- The Drive-in rack should be packed properly by using the steel belt and plastic film.

- All parts of the drive-in rack should be properly wrapped.

- Airbags should be placed at the interspace of containers which prevents collapse and collision of products.

- Placing rack sets over each other should be avoided.

- Place some material between the sets of the drive-in rack within the gaps.

- You should make sure that the packing is not wet from anywhere.

15. What is the Delivery Time of Drive-In Rack?

At first, the time taken during the manufacturing process is measured and it depends upon the manufacturer.

On average, manufacturers take a maximum of 3 to 4 weeks to manufacture and supply a set of the drive-in rack.

It includes complete delivery with shipment to the customer’s preferred location.

The delivery time can be delayed due to some geographical restrictions or the quantity of drive-in racks.

More time can be spent if there are specific requirements or the order quantity is greater than normal.

16. How to Install Drive-In Rack?

Before installing the drive-in rack, you should make sure that the team is professional and skillful.

Proper installation drawing should be made with guidelines and clarity.

After you have made a comprehensive plan and a well-understood drawing, start the installation process.

Follows these steps to install a drive-in rack in your warehouse:

- Place the rear pallet rack beam at the bottom and install it properly.

- Install the top rear beam above the bottom rack beam.

- After installation of both beams, install the top front and back front pallet rack beam.

- Install the slide supporting rails by fixing the single and double arms on the drive-in rack.

OKE Storage as a well-known supplier of the drive-in rack in China, we can provide you detailed install instruction or videos for every type of racking to help you save cost and time.

If needed, we can also send the engineer to your site to guide racking installation to help you save worry.

17. How to Maintain Drive-In Rack?

You can maintain a drive-in rack in the following ways:

- You should regularly inspect the quality of the drive-in rack and identify any defects.

- If defects found in the drive-in rack, repair them immediately.

- Assure that pallets are placed in the proper positions on the racks.

- Assure that the weight put on the rack is below its maximum capacity.

- Use appropriate accessories to prevent items from falling.

- Train your employees about the proper usage of the drive-in rack.

- Take advice from professional engineers before making any changes.

18. How Long is the Drive-In Rack Warranty?

The warranty period of the drive-in rack starts from its date of purchase.

Usually, the warranty for a drive-in rack lasts for 10 years.

It means that if you find any kind of defects in a drive-in rack you can replace it without paying anything.

But the warranty can be claimed under some rules prescribed by every warranty provider.

Damage cannot be claimed for warranty.

Therefore, the drive-in rack needs to be placed under a dry atmosphere in your warehouse. OKE Storage as the leading drive-in rack manufacturer and supplier in China, we have more than 20 years in this field and can supply you with a 10-year supper long warranty