Maximize Space with Drive-In Racking Systems

Drive-in racking systems are designed for high-density storage, allowing forklifts to drive directly into the racking structure. This innovative design optimizes vertical space while facilitating easy access to pallets. Ideal for bulk storage, these racks support a variety of load sizes and weights, making them suitable for warehouses and distribution centers.

ADVANTAGES OF DRIVE-IN RACKING

- Good Solution for Storage of Products with a Great Number of Pallets: Drive-In Racking accommodates high volumes of pallets efficiently, allowing multiple layers of storage. This is ideal for businesses managing large inventories, maximizing capacity within a compact footprint.

- Easy Management: Forklifts can access products directly from the front, simplifying loading and unloading. This reduces search time and enhances overall operational efficiency, streamlining inventory management processes.

- Highly Efficient Use of Warehouse Space: Drive-In Racking optimizes vertical space, increasing storage capacity without expanding the physical footprint. It minimizes aisle width, allowing for more products to be stored efficiently within the same area.

- Cold Room Storage: This racking system is suitable for cold storage, ensuring proper air circulation for temperature-sensitive products. It's perfect for perishable goods, maintaining freshness and integrity in industries like food and pharmaceuticals.

Since we installed the Drive-In Racking system, our warehouse space has been maximized, and managing our inventory has never been easier!<

Operations Manager

SF EXPRESS

(China, Shanghai)

DRIVE-IN RACKING APPLICATIONS

Food Distribution Centers

Beverage Warehouses

Retail Fulfillment Centers

Pharmaceutical Warehouses

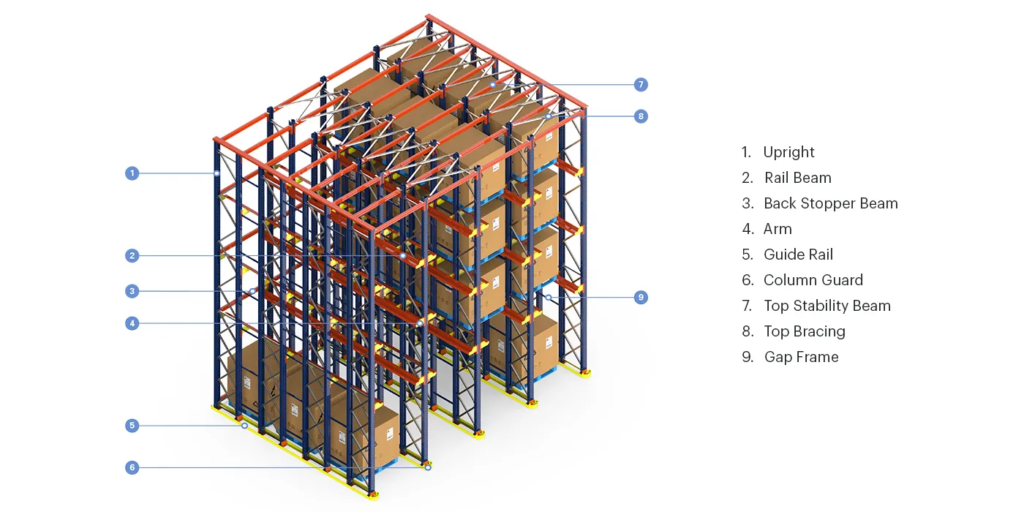

DRIVE-IN RACKING COMPONENTS

FAQS

Frequently Asked Questions About Drive-In Racking

Yes, drive-in pallet racking is a highly cost-effective storage solution. It can provide up to a 30% cost advantage compared to other storage systems with similar density. The average investment for a drive-in pallet racking system with two levels is approximately $70 per pallet position, making it an economical choice for maximizing storage efficiency.

To ensure the longevity and reliability of your drive-in pallet racking, consider the following maintenance practices:

- Conduct regular quality inspections to identify and address potential issues.

- Clearly label the maximum weight capacity for each rack section to prevent overloading.

- Provide comprehensive training for employees on safe usage and maintenance procedures.

- Promptly repair any damaged surfaces to maintain structural integrity.

To enhance the corrosion resistance of your drive-in pallet racking, consider using reputable manufacturers like SUHONG Storage Systems. Effective strategies include:

- Applying a durable powder coating, which is one of the best methods for preventing corrosion.

- Avoiding installation in humid or wet environments to reduce the risk of rust.

- Ensuring that the racks are placed in dry areas to maintain their integrity over time.

SUHONG Storage offers a warranty period of 10 years for their drive-in pallet racking systems. Warranty terms may vary by manufacturer, and claims can be made for defects not caused by external factors. Ensure that your drive-in pallet racks come with a warranty from the manufacturer to protect your investment.

About Your Supplier Nanjing Suhong Intelligent Storage Equipment

Absolutely. Suhong offers a complimentary technical visit where our storage solutions experts collaborate with clients to understand their requirements and goods flow, creating a customized warehouse layout tailored to their logistical needs.

We are a professional manufacturer of metal products and have our own factory.

The raw material is high-quality low-carbon steel q235.

Yes, we do custom products and projects.

Yes, we can make the best suitable design for you but do need to know the details.

Yes. Samples could be provided.

Plastic banding or Stretch film wrapped ensures safe delivery.

TT or L/C at sight, Trade Assurance, etc.

Yes. We will send you information and photos at the different production stages of your order. You will get the latest information in time.

It depends on the order quantity and types. In general, within 4-6 weeks, for an ordinary order quantity.

We take full responsibility for any manufacturing defect, would either refund or reship good products to you.